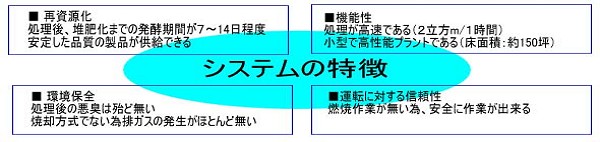

MRMの特徴

[[ Features of subcritical water reactor MRM]]

Recycling of Organic Waste "Subcritical Water Reactor"

The sub-critical water reaction type M recycling machine puts raw materials such as dewatered sludge cake, kitchen waste, and sawdust into a can, which is then subjected to high temperature (about 100 to 200°C) and high pressure (10 to 20 atm) saturated steam. Steaming process is performed while stirring the processed material with .

The equipment is small and the throughput is large

MRM II is 2.5m wide x 8m long x 4.5m high. Processes the amount of waste 2㎥ in 10 to 60 minutes.

No harmful substances, bad odors, or sewage generation

Subcritical water treatment (high-pressure steam treatment) does not require an incineration process, so there is no toxic dioxin, carbon dioxide, or nitrous oxide that causes global warming.

Disposes of all combustible waste

We can process all combustible materials, including organic waste such as food waste, organic sludge from sewers, incineration ash, paper shredder dust, vinyl for industrial and agricultural use, and construction waste.

No concerns about safety, hygiene, or maintenance

It is a safe, hygienic, maintenance-free device that emphasizes the benefits of introducing it to the user.

Treated waste turns into superior products

The treated product is sterile, residual toxic substances are below the safety limit, and when composting, the development of beneficial organisms such as yeast is surprisingly short-lived.